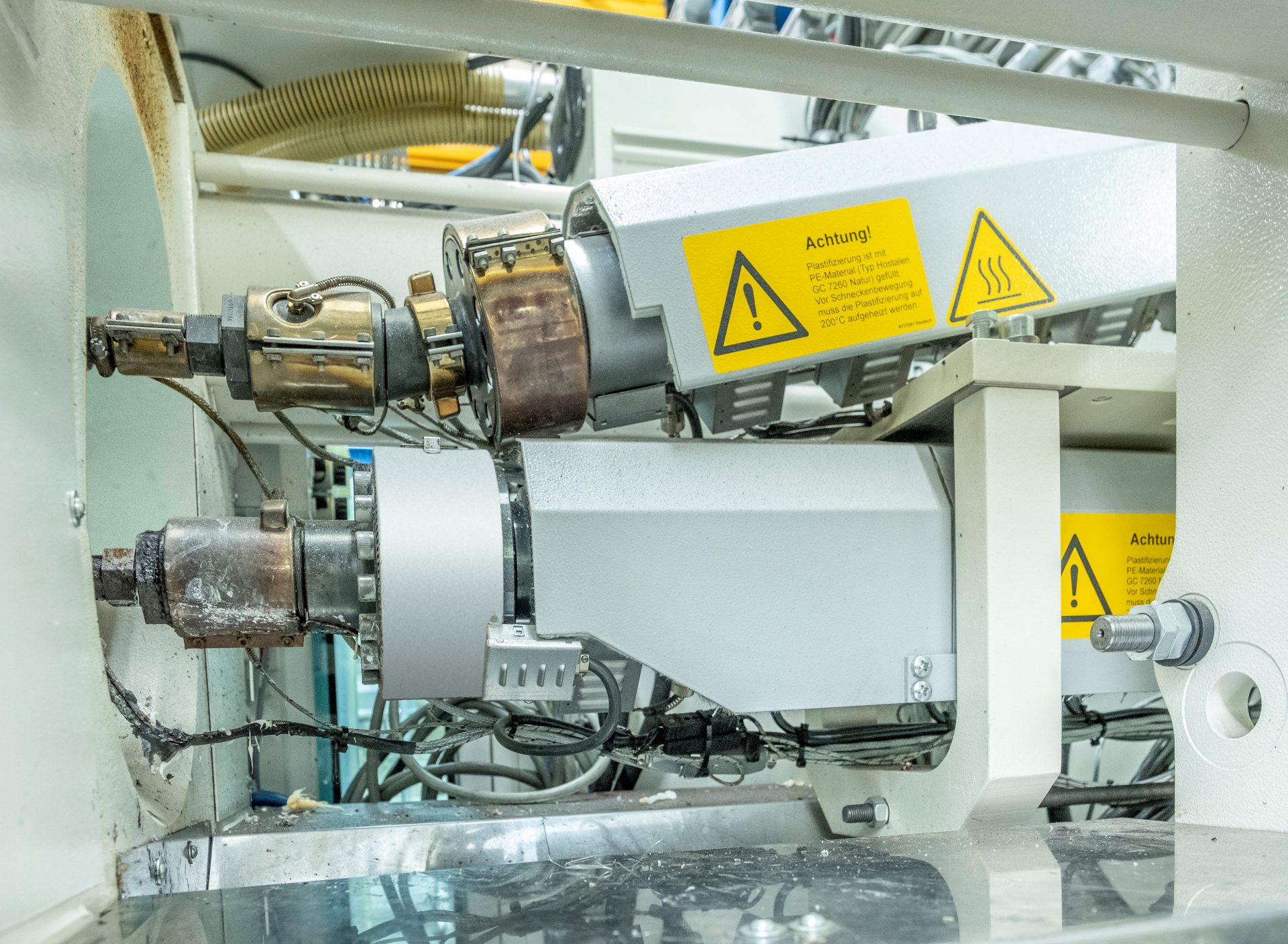

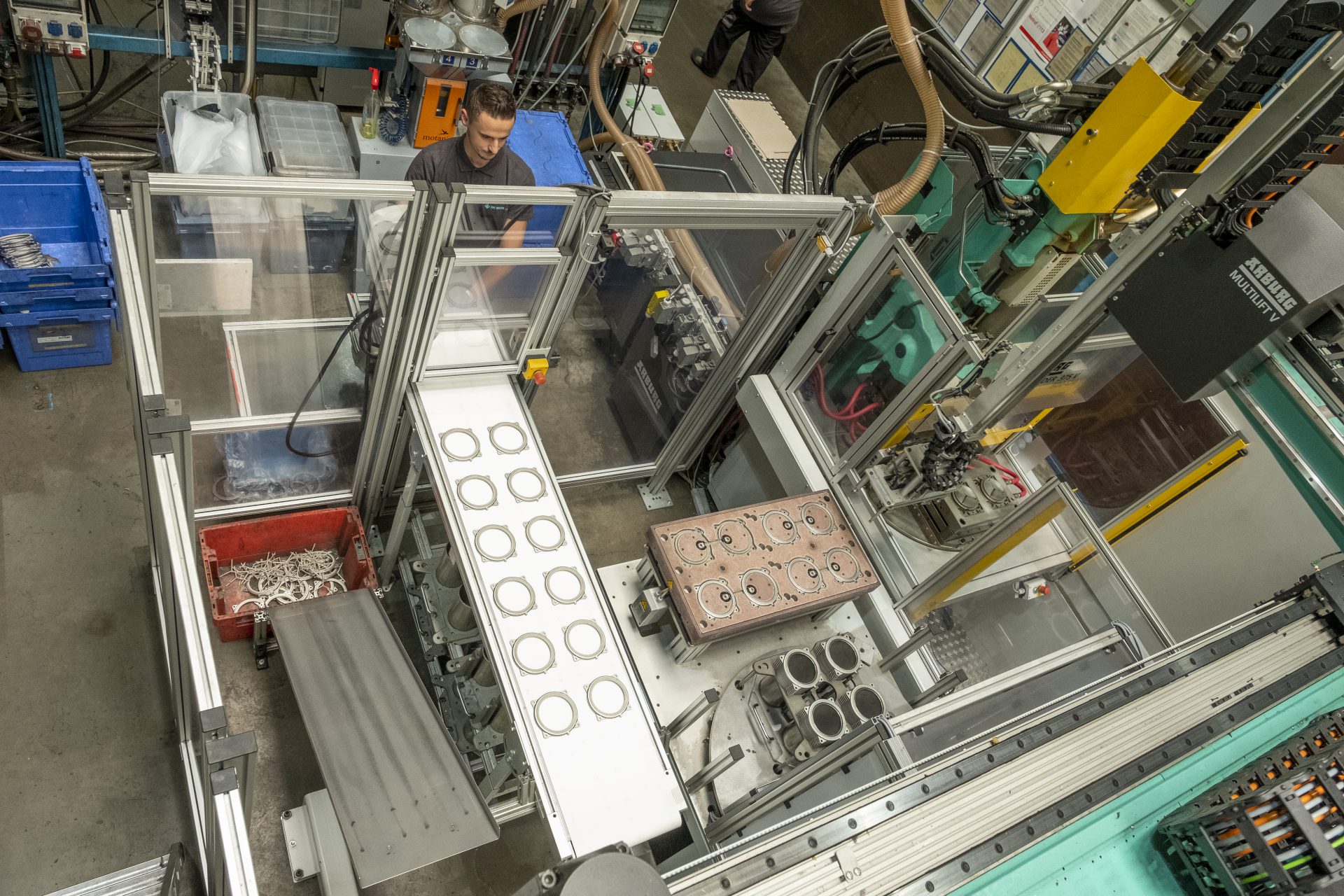

Our experience with soft plastics offers benefits in multi-component injection moulding. We produce products in 2K and 3K, combining hard and soft materials in the same product.

Thermoplastic elastomers (TPE) have the advantage that they can be bonded with other plastics during a production process. In most cases, this is a hard-soft bond.

Breidenbach has decades of experience in joining different materials within one product. 2-component injection moulding technology can have different purposes:

Would you like to know more about the possibilities of 2-component technology at Breidenbach? Please contact our specialists. We will be happy to inform you about what we can do for your product.

Contact us

Accountmanager OEM De Beer Breidenbach